|

Real time viewing of 1,500-foot guyed tower's erection in Florida is industry first

October 5, 2007 - Through the joint effort of Hark Tower Systems, Stainless LLC, Tower King ll and WirelessEstimator.com, real time viewing of the construction of a  1,500-foot guyed tower near Daytona Beach, Florida, will be presented until the project is completed. 1,500-foot guyed tower near Daytona Beach, Florida, will be presented until the project is completed.

Cox Radio Group awarded Stainless the project to replace their broadcasting tower that was knocked down during a tornado in February of 2007.

The nine guy anchor foundations were not damaged during the structure's collapse, but the base was retrofitted to accommodate the new tower. Sophisticated computer wind modeling techniques were employed by Stainless' tower engineers to ensure the safety of the new design under the most unusual environmental conditions.

This is the first time that the nation will be able to view, in real time, the construction of a tower on the internet, and it should prove to be especially interesting to the large audience of people who are intimately involved in the industry, but have never had the opportunity to witness the exacting disciplines, equipment and procedures required to safely erect a tower.

Joining this industry first is another milestone. This is the first tall broadcast tower erected in the country that has been designed using TIA-EIA 222-G, the nation's newest tower standard that became effective January 1, 2006.

Florida is currently the only state where Revision G is legally applicable. The 2004 Florida Building Code was amended December 8, 2006 referencing the newest revision of the structural standard.

Hark Tower Systems, well-known throughout the industry for their obstruction light monitoring, site access control and security equipment, designed the camera system and software necessary to provide excellent views of the construction as it takes place.

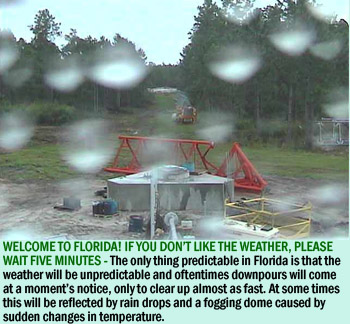

The camera required a 90-degree tilt capability in order to observe construction as the tower is erected to the 1,500' level. Using a wireless data SIM card to transmit the images in addition to providing a solar-powered system were unique to the project.

Mounted atop a 20-foot, 30-inch face tower provided by Stainless, the camera also ensures excellent security for the construction project. Randy Hargenrader, President of Hark Systems, has personally visited the tower site between Orlando and Daytona Beach numerous times to ensure the proper installation and operation of the camera.

Since its founding in 1947, Stainless has been a leading supplier of guyed and self-supporting towers for TV, radio, microwave and general communication industries. The manufacturer has the versatility of providing towers of any height up to 2,000 feet.

Stainless has built more than 7,500 towers in over 100 countries. The company's president, Don Doty, is a tireless advocate for increased safety awareness in the tower erection profession and currently serves as the Chairman of the National Association of Tower Erectors.

Tower King ll was selected by Stainless to erect the Daytona Beach structure. The company, specializing in heavy rigging, has erected some of the largest and heaviest tower structures in North America.

Originally founded by one of the pioneers in heavy tower construction, Jimmy (James Grover) King, who passed away in 1997, the Tower King name became an icon in the industry.

Kevin Barber, President, founded the latest incarnation as Tower King II and maintains King’s legendary reputation for quality and safety. Kevin will be on site for the stub setting on October 5, 2007.

The project manager is Charlie Lee. Foreman Kenny Singleton managed assembling and painting the structure's 50 sections for Tower King ll with the assistance of Jason Krepner who will become part of the top push team in stacking the tower. Seasoned veteran Owen Garland will be the erection project's foreman.

A Stainless 30"x140' track-style gin pole will be used to set the remainder of the tower sections and equipment once the crane sets the stub. The winch is a personnel rated HPSI 210 with high strength ¾" wire cable for personnel or material lifting.

Let others in your company know about this real time construction. They'll also appreciate the opportunity to see these tower professionals at work.

|