Service Information

Concrete and Soil Testing

The bulk of concrete testing for a greenfield or colocation site involves the requirement to provide compression testing of tower foundations and building and equipment slabs. If the PSI falls short of the specified strength following the last cylinder break, then destructive or non-destructive testing, such as core drilling, Windsor Probe or a Swiss Hammer Test is required to identify whether the test cylinders were faulty and the foundation meets code and the owner’s requirements.

Depending upon the project’s specifications, additional testing may be required such as concrete mix design testing, including a sieve analysis, for $75.00. Slump and air content tests may be required as well. Some specifications call for the testing firm’s representative to take the samples, at costs ranging from $35.00 to $50.00 per man-hour. The minimum fee for any testing service is usually $40.00 . If the contractor’s representative takes the cylinders, pickup of the completed cylinders by the testing laboratory, within a 30- mile radius, is around $30.00 for three cylinders. Some firms will charge $9.00 for each additional cylinder. The cylinder compression test (6”x12”cylinder, including mold – ASTM C 39) averages $15.00 per cylinder. Depending upon the project’s specifications, additional testing may be required such as concrete mix design testing, including a sieve analysis, for $75.00. Slump and air content tests may be required as well. Some specifications call for the testing firm’s representative to take the samples, at costs ranging from $35.00 to $50.00 per man-hour. The minimum fee for any testing service is usually $40.00 . If the contractor’s representative takes the cylinders, pickup of the completed cylinders by the testing laboratory, within a 30- mile radius, is around $30.00 for three cylinders. Some firms will charge $9.00 for each additional cylinder. The cylinder compression test (6”x12”cylinder, including mold – ASTM C 39) averages $15.00 per cylinder.

Soil Compaction

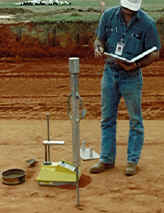

Compaction is the process of making soil denser by squeezing air out of the voids. It is required on wireless construction projects to decrease compressibility, and to help reduce the effects of frost heaving. Although the standard proctor is used in some instances, most construction documents specify the modified proctor as detailed by ASTM D-1557. The modified proctor, used to test the compaction characteristics of the soil, averages $100.00 for each location. The compaction testing averages $50.00 per lift. If the specifications require that you have an on-site soils technician for observation and testing, budget $50.00 per hour. out of the voids. It is required on wireless construction projects to decrease compressibility, and to help reduce the effects of frost heaving. Although the standard proctor is used in some instances, most construction documents specify the modified proctor as detailed by ASTM D-1557. The modified proctor, used to test the compaction characteristics of the soil, averages $100.00 for each location. The compaction testing averages $50.00 per lift. If the specifications require that you have an on-site soils technician for observation and testing, budget $50.00 per hour.

Compaction testing is nuclear

Although other compaction equipment is used, most testing is done by a nuclear density meter. It is an easily portable device employing a radioactive isotope to determine the density of pavement layers, including earthworks, granular materials, bituminous materials and road pavement concrete Although other compaction equipment is used, most testing is done by a nuclear density meter. It is an easily portable device employing a radioactive isotope to determine the density of pavement layers, including earthworks, granular materials, bituminous materials and road pavement concrete

Simply put, it is the ability of the nuclear density meter to pass very small amounts of radioactivity through the various materials that require testing, and to measure the responding amounts of radioactivity returning to the measuring head of the meter. The less dense a material is the easier radioactivity will pass through it.

We recommend that you contact our listed concrete and compaction testing companies to obtain additional information about their services, capabilities and experience.

Testing for imperfections, just listen to the bouncing balls

In testing concrete for structural imperfections there are many different methods ranging from the drilling of core samples to the use of radar. The first method is destructive and allows for only a small percentage of the total area, while the second requires expensive equipment and is not always effective when steel reinforcement is present. The National Institute of Standards and Technology (NIST) has developed a non-destructive method for testing the internal structure of concrete. Steel balls are dropped onto the concrete surface causing sound waves, which are reflected by cracks and other imperfections in the concrete. These sound waves can then be collected and analyzed by a neural network to determine and plot the probability of a flaw.

E-Testing? It is not too far away!

When surveyors first showed up on the jobsite with state-of- the-art GPS surveying tools a few years ago, seasoned contractors shook their heads in amazement. Imagine calling a concrete testing firm to take cylinders and the technician arrives with a computer, scans a small sample of your concrete and in two hours, he documents what the 28-day strength of the concrete will be.

NIST researchers and industry partners intend to make that a reality. They recently launched the Virtual Cement and Concrete Testing Laboratory Consortium to develop a computer-based or “virtual” laboratory that could quickly evaluate cement and concrete mixtures.

|