Product Information

Foam Coaxial Cable

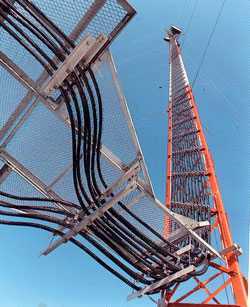

Coaxial cable is the medium used to connect the transceiver equipment to the antennas. Coax comes in several types and sizes. The different types vary from braided outer conductors and smooth wall to corrugated. Sizes range from 1/4” diameter to 2-1/4” for foam cables and up to 6-1/8” in diameter for air dielectric cables.

The cable is called "coaxial" because it includes one physical channel that carries the signal surrounded by another concentric physical channel, both running along the same axis.

Foam coax, almost exclusively used in wireless applications, ranges in size from 1/4” “superflexible” cable to 2-1/4” “foam” cable. The foam refers to the dielectric material between the inner and outer conductors. Air dielectric cable has polyethylene spiral spacers. The outer conductor protects against electromagnetic interference (EMI) and radio frequency interference (RFI). The current of the inside and outside conductors flow in opposite directions causing the outer conductor to cancel the magnetic field of the inner conductor. Coaxial cables offer excellent phase stability over temperature variations and with bending.

The polyethylene jacket provides abrasion resistance and environmental protection. Coaxial cables are available with special jacketing to meet fire retardant standards required by local electrical codes. In some jurisdictions when the cable penetrates more than one floor of a building, but does not enter air-handing premise space, a fire retardant non-halogen riser rated cable is required; otherwise a fire retardant riser rated cable will be required for use within buildings where electrical codes require cable rated as CMR or CATVR. The polyethylene jacket provides abrasion resistance and environmental protection. Coaxial cables are available with special jacketing to meet fire retardant standards required by local electrical codes. In some jurisdictions when the cable penetrates more than one floor of a building, but does not enter air-handing premise space, a fire retardant non-halogen riser rated cable is required; otherwise a fire retardant riser rated cable will be required for use within buildings where electrical codes require cable rated as CMR or CATVR.

Superflexible cables in 1/4”, 3/8” and 1/2” sizes are generally used for jumpers that connect various parts of transceiver equipment, and from the transceiver equipment to the “main” coax line as well as to the antenna. They are also utilized for jumpers used to connect test equipment to the coax/antenna system; however, phase stable jumpers are recommended by test equipment manufacturers. Because of their small size, these cables are easy to use in tight places but have more loss than their larger counterparts. A 7/8” superflexible cable is also available.

A 1/2” foam coax is typically used as jumper material to connect main lines to antennas and/or tower mounted amplifiers. Sometimes in short run applications, it can and will be used as the only feed line in the system, going directly from the transceiver equipment to the antennas. The larger coax is used almost exclusively as the main transmission line from the equipment to the antennas, with or without jumpers at either end.

The larger size coax has lower loss and higher power handling capabilities. Some of the main decisions to make when it comes to purchasing coax are lower loss versus higher cost and more tower loading. Challenging installations, especially with in-building broadband applications, will also affect the purchasing decision when flexibility is required. Manufacturer’s warranties are between 5 and 10 years. Some manufacturers offer coaxial cable in UV stabilized colors such as white, blue and gray.

|

Standard Coaxial Cable Averages (50 Ohms)

|

| Cable Size |

List Price |

Discounted Price |

Maximum Frequency GHz |

Minimum Bending Radius Inches |

Weight Lbs. Per Ft. |

Diameter Inches |

Tensile Strength Lbs. |

| 1/4" Superflexible Coax |

$1.92 |

$1.27 |

20.40 |

1.00 |

0.048 |

0.300 |

138 |

| 3/8" Superflexible Coax |

$2.73 |

$1.93 |

13.40 |

1.13 |

0.078 |

0.433 |

193 |

| 1/2" Superflexible Coax |

$4.20 |

$2.99 |

11.78 |

1.25 |

0.128 |

0.506 |

187 |

| 7/8" Superflexible Coax |

$5.83 |

$3.47 |

4.90 |

5.00 |

0.290 |

1.081 |

225 |

| 1/4" Foam Coax |

$1.47 |

$1.06 |

18.60 |

2.00 |

0.090 |

0.382 |

110 |

| 3/8" Foam Coax |

$2.10 |

$1.44 |

13.73 |

3.25 |

0.097 |

0.448 |

174 |

| 1/2" Foam Coax |

$2.78 |

$2.00 |

9.05 |

4.75 |

0.153 |

0.628 |

337 |

| 5/8" Foam Coax |

$4.86 |

$3.22 |

6.15 |

7.50 |

0.225 |

0.853 |

280 |

| 7/8" Foam Coax |

$6.56 |

$4.69 |

5.08 |

10.00 |

0.300 |

1.113 |

494 |

| 1-1/4" Foam Coax |

$12.44 |

$8.52 |

3.43 |

15.00 |

0.697 |

1.542 |

950 |

| 1-5/8" Foam Coax |

$16.28 |

$11.67 |

2.64 |

20.00 |

0.873 |

1.915 |

1013 |

| 2-1/4" Foam Coax |

$22.31 |

$17.11 |

2.20 |

23.00 |

1.255 |

2.355 |

1044 |

| |

Wireless Estimator average of all major coaxial cable manufacturers |

|

Coaxial cable list pricing is fairly competitive; so much so that in certain sizes multiple manufacturers publish the identical price. Discount levels per customer can have a varied range based upon the manufacturer and the volume of business being provided. Some vendors’ list price reductions will be based upon an agreement to purchase a contracted amount of transmission line; others will base it upon the total volume of products purchased during the year, some will calculate it upon your month-to-month buying volume. For estimating purposes, the default pricing, as detailed above, is a discounted amount that should be obtainable through most manufacturers and distributors for standard cable for any appreciable volume. Check with your vendor to obtain current pricing on specialty coaxial cables such as plenum rated transmission line. Coaxial cable list pricing is fairly competitive; so much so that in certain sizes multiple manufacturers publish the identical price. Discount levels per customer can have a varied range based upon the manufacturer and the volume of business being provided. Some vendors’ list price reductions will be based upon an agreement to purchase a contracted amount of transmission line; others will base it upon the total volume of products purchased during the year, some will calculate it upon your month-to-month buying volume. For estimating purposes, the default pricing, as detailed above, is a discounted amount that should be obtainable through most manufacturers and distributors for standard cable for any appreciable volume. Check with your vendor to obtain current pricing on specialty coaxial cables such as plenum rated transmission line.

Include taxes and freight in your estimate. Use the average weight per foot calculations above for the total cable weight, but have your distributor provide you with the total weight and type of shipping material that will be used. Cartons can be typically used for up to 500’ of 1/2” coax. Depending upon the cable size and length of your order, other packing methods might be wood boxes or disposable and returnable reels ranging in diameter sizes from 34” to 129”.

We recommend that you contact our valued coaxial cable manufacturers and distributors for your project-specific transmission line requirements.

Check to see that they didn’t switch coax Check to see that they didn’t switch coax

When you’re providing the coax in your proposal, carefully review the specifications. It’s easy to get into the habit of assuming that you’ll be providing the same cable that you are used to purchasing. There are numerous new cables being specified that provide less attenuation as well as more flexibility. An increase in pricing typically accompanies the benefits. Carriers will change the specified manufacturer’s feeder cable or identify a new vendor to provide efficiencies for a new system design, but they’ll seldom accent the change in the specifications.

VSWR important in cable selection

Coaxial cables detailed as “standard” by the manufacturer have characteristics which meet broad specifications for VSWR. In example, a standard cable may have a maximum VSWR of 1:20:1 at frequencies to 2MHz.

Formerly called premium cables, low VSWR cables by frequency range can vary from one manufacturer to another, such as a maximum 1:15:1 VSWR for one cable manufacturer while another lists their maximum at 1:10.1. A cable listed by the manufacturer as standard with a maximum VSWR of 1:20:1 from 100 MHz to 2 GHz could have a classification as a low VSWR cable for 800-900 MHz if the maximum VSWR between these frequencies was 1:10:1 or better. VSWR values may also vary with the cable’s length and the type of connector that is used such as a DIN, Type-N, etc. range can vary from one manufacturer to another, such as a maximum 1:15:1 VSWR for one cable manufacturer while another lists their maximum at 1:10.1. A cable listed by the manufacturer as standard with a maximum VSWR of 1:20:1 from 100 MHz to 2 GHz could have a classification as a low VSWR cable for 800-900 MHz if the maximum VSWR between these frequencies was 1:10:1 or better. VSWR values may also vary with the cable’s length and the type of connector that is used such as a DIN, Type-N, etc.

The attenuation and average power figures listed below are coaxial cable averages to identify the approximate values a purchaser can expect from cable purchased. Check the manufacturer’s specification sheet for products with the properties that will meet your specific design requirements.

Flexible Cable types vary

Corrugated cables:

The outer conductor of the cable is corrugated, and depending upon the size of the cable, it has either a corrugated, smooth wall or solid inner conductor. Between the outer and inner conductor is a foam polyethylene dielectric material. The corrugations provide an element of flexibility to the coaxial cable while still maintaining structural integrity and 100% shielding of the inner conductor.

Smooth wall cables:

A lower loss is obtained by using smooth wall cables that utilize a smooth wall for the outer conductor. The inner conductor, depending upon the size of the cable, can be solid or a smooth wall tubing. Polyethylene foam is sandwiched between the conductors to provide the dielectric material. They are not as flexible as corrugated cables, but maintain similar minimum bending radii.

Braided cables:

Constructed with a braided outer conductor and a solid wire inner conductor, braided cables are available in multiple sizes, Some braided cables use a metallic sheath which encases the cable and serves as the outer conductor, allowing the braid to allow flexibility and strength. As with smooth wall and corrugated cables, both conductors are separated by a polyethylene foam dielectric material.

Air Dielectric cables:

Air dielectric cable is similar to a corrugated cable, but instead of foam it has a polyethylene spiral spacer. The coax must be pressurized for exterior applications, but some cables do not require pressurization if used in a controlled indoor environment. They’re designed to provide a lower attenuation and higher average power rating than foam coax.

|