OVER FIFTY YEARS IN THE DESIGN STAGE – Since 1971, Jim Mayfield had sought a better gin pole that would be more versatile, easier to install, and safer. His relentless drive resulted in Matt’s Arm becoming the contractor’s gin pole of choice, especially since it can drastically reduce crane and other costs.

Matt’s Arm is the newest tool in the tower industry, and contractors say there is no other tool that is so versatile since it adapts to most all tower types and lifting needs. It’s quickly becoming an essential tool for contractors’ crews.

For decades, there had yet to be a serious design change in an industry stalwart, the venerable but cumbersome gin pole, until designer and owner Jim Mayfield recently introduced Matt’s Arm.

Mayfield has been in the tower industry since 1971 and said he always had that underlying feeling that there had to be a more accessible, safer, and more economical way to change out or install cell site antennas and sector mounts.

He found it after he designed and patented it. Matt’s Arm is recognized as the most unique and versatile lifting device in the country.

Mayfield said consulting engineer Bill Griswold, with 22 years in the industry, guided the design and integrity of Matt’s Arm for safety, efficiency, and load capacity.

Mayfield and Griswold said they are committed to making the industry safer and more efficient for crews, contractors, and carriers.

IT CAN BE USED FOR TELECOM STRUCTURES AT ALL LEVELS

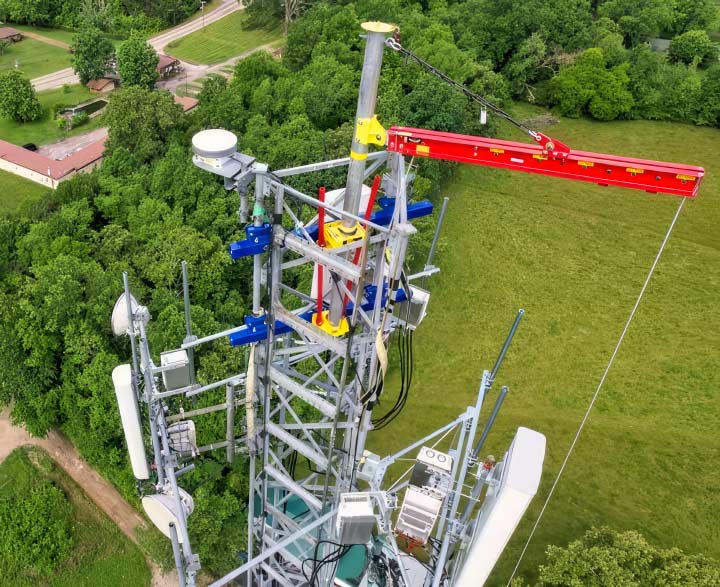

Matt’s Arm, with the mast pipe, assembled on the ground, flying up for installation at the top of a guyed tower.

Mayfield said that Matt’s Arm securely attaches to monopoles, self-support, and guyed towers above the top of the tower and between sector mounts.

It is lightweight, modular, portable, and can be carried in the crew’s work trailer.

Its unique design allows it to reach all sectors on a 42-inch face without relocating, and it has a lifting capacity of up to 1,600 pounds.

Another key benefit is that a crew can install Matt’s Arm in two hours or less.

SAFETY AT THE TOP AND A VERY ATTRACTIVE BOTTOM LINE

Matt’s Arm significantly saves administrative time, project management, coordination, and crew scheduling. The average crane savings on the last five uses of Matt’s Arm were each over $20,000.

The modular design of Matt’s Arm allows for six configuration options that are securely attached to the tower, allowing more stable options than a traditional gin pole.

Matt’s Arm allows crews to customize the equipment to meet the needs of the tower specifications and projects.

The configurations move the load to the tower, dramatically reducing the need for tag line pressure, and they reduce the load line angle.

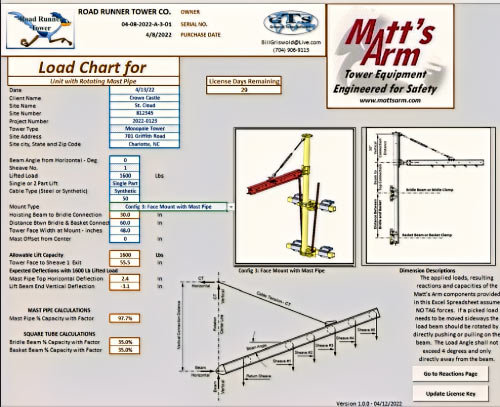

A customized load chart calculator for all configurations was customized by noted industry engineer Bill Griswold.

A customized interactive load chart calculator, designed explicitly for Matt’s Arm configurations by Griswold, gives assurance that the equipment has been installed within safe working load limits. It also provides calculations on reactions on the tower, further confirming the integrity of Matt’s Arm design.

The beam and the mast pipe are strong and lightweight, made of 6061T6 structural grade aluminum. The structural steel clamps are engineered to attach securely to the tower, much like sectors are held in place with clamps.

Color coordinating of the equipment makes assembly easy and user-friendly. Crews using Matt’s Arm find it easy to install, strong, portable, and so compact that it fits in their work trailer or truck.

Every connection point and component meets and exceeds industry safety factors. There are no loose connection points with Matt’s Arm equipment. Every component is designed to provide a strong, positive attachment to the tower structure.

UNIQUE DESIGN ALLOWS ASSEMBLY AT THE GROUND OR TOP

Matt’s Arm is uniquely designed for assembling on the tower or on the ground. The beam’s reach, up to 8′ from the tower, allows clearance over lower sectors and torque arms with little or no tagging. The beam’s five sheaves, spaced 12″ apart, allow the crew to lift and land the load precisely where it needs to attach to the tower.

A unique feature of the Matt’s Arm mast pipe is that it can be installed inside the tower providing maximum reach to all three sectors. Matt’s Arm configurations that do not use the mast pipe can be installed in very tight spaces between sectors for working below the top of the tower.

The rotation of the beam in these configurations is +/- 90°, allowing two sectors to be reached with one setup.

Matt’s Arm’s equipment may be purchased as a kit (all 6 configurations) or individual configurations depending on contractor needs.

For additional information, visit www.mattsarm.com .