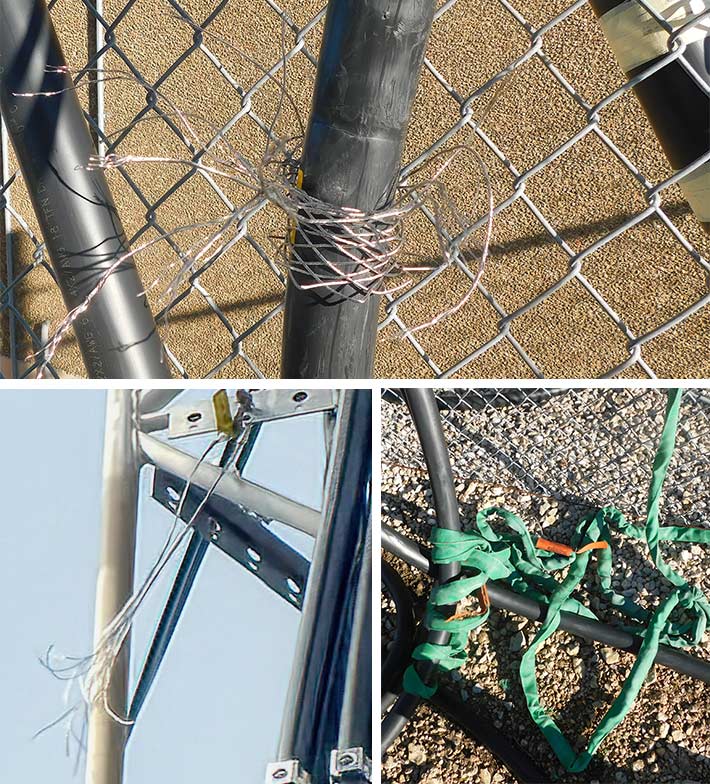

THIS HOISTING GRIP that came pre-attached to the hybrid cable manufactured by Huber+Suhner failed, resulting in the death of a Texas tower tech last month. Investigators are currently trying to determine if it failed because it couldn’t support the working load, whether it was shock loaded or failed for another reason. Although there have been numerous failures throughout the years of hoisting grips, this is the first known instance where a life was lost – forcing the industry to address the use of grips that are not designed for hoisting and have not been tested to perform a rigging function.

Huber+Suhner has issued an urgent notification not to use pre-laced hoisting grips installed on all Masterline Classic Hybrid 12×24 cable that came attached to the hybrid cable when reels were delivered to installers or may be sitting in stock at customer warehouses.

The notice was prompted after a pre-laced hoisting grip on a Huber+Suhner hybrid cable failed on December 15, 2022, resulting in the death of a 32-year-old Texas tower technician when the line fell and struck him while he was working on an American Tower Corp. guyed tower for a Verizon installation.

The notice is AVAILABLE HERE.

In its notice, Huber+Suhner said, “The use of any kind (e.g., to pull up, affix the hybrid assembly to a structure, and/or to support the weight of the cable in any manner) of the pre-equipped/affixed Pre-Lace Hoisting Grip is immediately prohibited. For any products in stock that come assembled or equipped with a Pre-Lace Hoisting Grip, the Pre-Lace Hoisting Grip should be rendered unusable per the attached instruction. HUBER+SUHNER now requires that installation of the hybrid cables be performed via alternate means.”

Following the incident, the proper use of hoisting grips became a significant safety concern in wireless construction, and industry experts are mobilizing to address the problem.

Most companies prohibit the use of hoisting grips to raise communications cable, but others follow the manufacturer’s recommendation.

Safety professionals believe that the term “hoisting” grip is incorrect since they are not to be used to hoist cable, and manufacturers do not provide a working load limit easily identified by the installer. Although some manufacturers provide the grip’s breaking strength, that limit provides insufficient information for a safe pick.

As an example, one manufacturer, FIMO, on their product data sheet, identifies that its hoisting grip has a breaking strength of 1350N. Ask a foreman or tower tech, or other professional to calculate newtons to a force, and they’ll likely be scratching their heads.

FIMO’s mounting instructions show that you can lift cable by attaching your load line to the hoisting grip, with the caveat, “Make sure that the proper hoisting grip is used for the cable or waveguide being installed.”

However, FIMO provides no information as to what the proper hoisting grip should be, although it appears that their hoisting grips are designed to pick coaxial cable, elliptical waveguide, and hybrid cable – all of which have different weights per pound, but might be similar in diameter.

FIMO is not alone in issuing an imprecise hoisting guideline that many manufacturers use: “Use hoisting grips at intervals of no more than 200 ft.”

“Maintain tension on the hoisting grip during hoisting. Loss of tension can cause dangerous movement of the cable or waveguide and result in injury or death to you or others on or near the tower,” FIMO cautions.

Although manufacturers state that the cable should be dressed with hanger kits or other attachment hardware before releasing the transmission line from the secured hoisting grip, they do not identify any percentage of the cable’s length before it can be fully supported.

It is well-known throughout the industry that many transmission lines inside monopoles are secured solely by hoisting grips.