|

Corrosion of anchors above and below ground put many guyed structures at risk of collapse

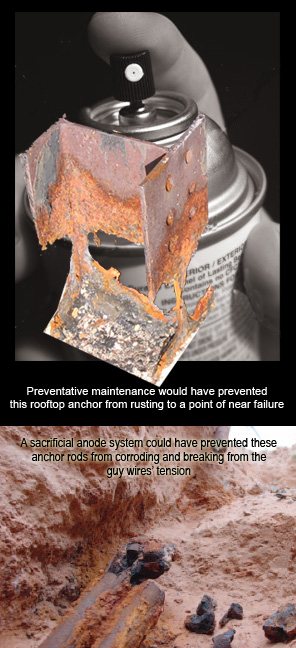

December 28, 2006 - There has been considerable focus upon the need to inspect  guyed tower anchor systems below ground to ensure that their rods or channel iron are not corroding to the point of failure. With approximately 25,000 guyed towers nationwide, many of the structures might be at risk of collapse. Guyed towers on the top of buildings are also at peril if their anchors have not been properly inspected and maintained. guyed tower anchor systems below ground to ensure that their rods or channel iron are not corroding to the point of failure. With approximately 25,000 guyed towers nationwide, many of the structures might be at risk of collapse. Guyed towers on the top of buildings are also at peril if their anchors have not been properly inspected and maintained.

In 1991, OSHA issued a Hazard Information Bulletin addressing Communication Tower Guy Anchor Corrosion . The agency was prompted to provide the HIB after learning of a North Dakota tower collapse that was caused by an anchor failure. A three-man tower crew plumbed and tensioned the structure as part of their inspection program. Two climbers then began to ascend the 350-foot tower when an anchor shaft supporting five guy wires separated where it entered the buried deadman concrete base, three feet below ground level.

The structure collapsed and the workers miraculously survived, but received serious injuries. This was not an isolated incident of industry workers almost falling to their death following a guyed tower collapse due to corroded anchorage.

During the 1990's, two climbers from an Orlando, Florida service company were dismantling a Rohn 25G structure from the roof of the City of West Palm Beach Police Department's communications division. Both men were near the top of the tower when a corroded anchor broke in two.

Climbers sue tower owner

The climbers fell with the tower which proceeded to fall off of the building, pinning one tower hand underneath it. City EMS workers were filming a training program less than a block away and their immediate response was credited with saving the lives of the seriously injured workers.

An inspection by a metallurgist found that the anchor had corroded to approximately a sixteenth of an inch of steel. The eyebolt anchor went through the membrane roofing system and was bolted to one of the roof's support structures. However, there was a pitch pan at the anchor's entry point and the bitumen allowed water to remain below the surface for many years.

The injured unemployable tower techs received full benefits from Workmans Compensation and later sued the City of West Palm Beach for not maintaining the anchors. The contract between the company dismantling the structure and the City stated that if it was found, after further investigation by the workers, that the rusted structure was not safe enough to remove the tower, section by section, that additional charges for a crane would be added.

The City's communications director said that the contractor stated that their employees tested the guy wires before climbing the tower. The plaintiffs also sued a South Florida contractor for installing the tower and not maintaining it as well as not providing a suggested maintenance program to ensure the integrity of the anchors. Depositions acknowledged that a city employee had mistakenly identified the tower erector who had no knowledge of the installation. An undisclosed settlement was awarded to the climbers.

OSHA's HIBs are neither standards nor regulations and it may not be a violation if a company turns a blind eye to possible anchor corrosion problems and does not implement OSHA's recommendations. However, under OSHA's general duty clause, employers must provide a workplace free from recognized hazards likely to cause death or serious physical harm.

Some safety consultants believe that a tower owner could be cited for violating the general duty clause because they did not take steps to prevent or abate guy anchor corrosion that OSHA's HIB identifies as a hazard.

"It is becoming increasingly clear that structural damage due to underground corrosion is not an isolated problem, but is widespread throughout the U.S. and Canada," explained Matthew Arps, General Manager of AnchorGuard®, a company specializing in corrosion control systems for tower anchors.

"Guy anchors are coming of age, and if they're not inspected and protected soon, many more tower anchors are likely to fail," he said.

"Over the past couple of years, investigations have revealed that up to 15% of the towers we have inspected have had structurally damaged anchors that required replacement. A very high percentage of others have had significant corrosion but didn't warrant replacement," Arps said.

Arps' recommended actions are to:

-

Develop a plan to target towers most at risk, and investigate

-

Perform surface and subsurface investigation of the anchors to determine if

structural damage has occurred

-

Install a corrosion control system that allows for continuous monitoring such as a sacrificial anode system

-

Regularly inspect the corrosion control system to ensure it is working properly

Matthew Arps will be discussing anchor system failures during an educational session on February 13, 2007 in Nashville during the National Association of Tower Erectors' conference and exposition.

|