|

|

|

|

|

|

|

|

|

| October |

1

Sections built, painted, guy wire prepared

|

2

Sections built, painted

|

3

Sections built, stub assembled

|

4

Sections built, painted, crane sets up

|

5

Stub set with first level of guy wires. Track pole set. Height: 226'

|

6

Checked track pole rigging. Ran wiring and installed first lighting level.

|

7

DAY OFF |

8

Minimal activity. Crane removed and tower sections painted. |

9

Minimal activity.

Painted sections, built remaining tower sections. |

10

Minimal activity.

Painted and added electrical conduit and climbing ladder to sections. |

11

Minimal activity.

Jumped gin pole and positioned sections for stacking.

|

12

Stacked 180'. Used back leg standoff to install second level guy wire. Height: 406'.

|

13

DAY OFF |

14

DAY OFF |

15

Stacked 120'. Ran electrical conduits for lighting. Height: 526'.

|

16

Stacked 90'.

INTERMITTENT

COVERAGE. Set third guy level.

Height: 616'.

|

17

INTERMITTENT

COVERAGE. Height: 706'.

|

18

INTERMITTENT COVERAGE. Height: 796'.

|

19

Stacked 210'. Used back leg standoff to install fifth level guy wire. Height: 1,006'. Good coverage.

|

20

Thunderstorms throughout the day.

|

|

21

Thunderstorms throughout the day.

|

22

Stacked 90'. Ran conductors for lighting system. Height: 1,096'.

|

23

Stacked 90' today and installed the 6th level guy wires.Height: 1,186'.

|

24

Most on site activity was out of camera range. Transmission line bridge built in PM.

|

25

Stacked 60'

Transmission line bridge built in PM. Height 1,246'.

|

26

30-mph top winds and rain prevented stacking. Transmission line bridge work in AM.

|

27

Thunderstorms throughout the day.

|

|

28

Unable to stack due to high winds at top of tower.

|

29

High top winds and rain prevented stacking. Installed conduit in AM.

|

30

High winds and rain prevented stacking. Installed transmission line in AM.

|

31

No work performed today other than removing temporary guy at lower level.

|

|

|

|

|

|

A double tip of the hardhat to Excell Communications and B and C Contracting for allowing the many thousands of daily WirelessEstimator.com viewers to be able to see the final stages of construction. On two occasions, both companies sent two men out to the job site and were able to identify why the camera's power supply had been failing on multiple mornings. Great job, guys!

|

|

Regarding cost, Wikipedia.com lists the cost of 1963 built 2,063 foot KVLY-TV mast in North Dakota as $500,000 in 1963 dollars ($3.3 million in 2007 dollars).

That's $1.6 million per 1,000 foot high in 2007 dollars for that old tower.

Does today's guy-wire tower cost less, or much, much less than before? Or does the cost stay about the same as before?

- Belle Mead, NJ

Site conditions, sub-surface conditions, location (heavy ice, no ice, hurricane possibility or not) and equipment loading all can produce widely varying pricing.

Based on that limited set of parameters, it's about the same.

|

|

Do you have any photographs of what it looks like from the top of the tower?

- Sioux Falls, SD

We have added a number of photographs of the top hands' view of the 90-foot antenna mast being installed on November 10, the last and longest section to be winched by the gin pole.

With little head room clearance, it was a professional challenge for the crew.

|

|

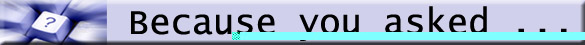

Can you explain the difference between fastest mile and three-second gust? - Rajawali Citra Television, Jakarta, Indonesia

As required by TIA/EIA 222-F, wind loading in the United States is calculated according to the fastest-mile wind speed for the structure's location as recorded from the 1-in-50-year wind speeds encountered at that location that were constant over a distance of one mile.

This is calculated differently in Revision G. It was changed because the government has stopped measuring wind in this manner, using a more accurate and larger set of wind measurements.

The new revision requires that wind loading be calculated according to the three-second-gust wind speed, allowing the tower's design to accommodate instantaneous loads.

Most National Weather Service sites record three-second gust wind speeds which will provide for more accurate averages for Rev G and future revisions. Additional information on Rev G is available here.

|

|

A well-respected tower design engineer says that the above answer implies a number of things that are not quite so. For further information, click here .

|

|

Why are what looks like ice shields being installed above the STL dishes on a tower in FLORIDA? - Bartow, FL

While rare, Florida does on occasion experience icing conditions. Up 1,000 feet or more, away from the ground, temperatures are colder.

Because of existing moist conditions and a strong cold front, ice indeed can form at the top of the tower. Putting up ice shields adds system reliability for very few dollars.

Insurers recognize the potential for freezing from Daytona Beach north and will not issue homeowner's insurance unless homes have an operating heating system to prevent pipes from freezing.

|

|

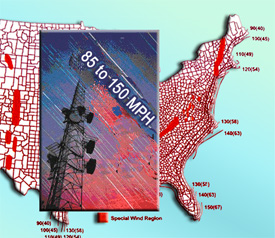

What method is being used to make sure the guy wires are properly tensioned? -

Salisbury, MD

Initial tension may be measured by vibration frequency, mechanical tension meters, measurement of guy sag, or by other suitable methods.

Direct and indirect are the two common methods of measuring guy tension on towers. The direct method uses mechanical or hydraulic equipment to pull the guy wire to measure the tension with a calibrated gauge. The indirect method uses assumptions and calculations to predict the tension. The most common application of this method is the Tangent Intercept method which was used in this project.

A line of sight is established which is tangential to the guy wire near the anchor end and which  intersects the tower leg a distance (tangent intercept) below the guy attachment point on the tower. This tangent intercept distance is either measured or estimated and the tension is calculated from using an equation provided in TIA/EIA 222-G. intersects the tower leg a distance (tangent intercept) below the guy attachment point on the tower. This tangent intercept distance is either measured or estimated and the tension is calculated from using an equation provided in TIA/EIA 222-G.

The guy transit that Tower King ll uses to accurately check intercepts is a high powered gun scope bolted to a precision machined body with a brass clamping system by Schrader Broadcast Services, Inc. It is adjustable and can be used for 5/8" wire to 3 ½" wire as pictured at right.

Another indirect method is to cause the guy wire to swing freely from side to side while timing the complete number of swings completed in a minute.

|

|

Finally, there is an addiction that's good for America's communications companies…your web site. Thanks for all of your great information. Can you provide some more details on the winch such as the wire size and if it is tied down? Also, is it a winch or a hoist? - Cheyenne, WY web site. Thanks for all of your great information. Can you provide some more details on the winch such as the wire size and if it is tied down? Also, is it a winch or a hoist? - Cheyenne, WY

The proper name is a hoist, but there are many old-time professionals that still call it a winch, and will continue to do so long after they're retired. The hoist is secured by dead man anchors attached to a steel skid. The hoist has a 210 horsepower diesel engine with a two speed, operator selectable, HI-LO winch speed system, and a 100-gallon fuel tank. Wire sizes for the three drums are two 3/4" and one 3/8" high strength wire rope.

The rear drum meets OSHA requirements for personnel lifting. The hoist has a hydraulic seat that allows the operator to incline so that he can safely view personnel and loads as they're lifted and lowered. The price for a new unit? A guesstimate is somewhere north of $300,000.

|

|

How fast can the hoist safely lift the tower erectors? - Mesa, AZ

An OSHA directive, CPL 2-1.36 , says, "The maximum rate of travel shall not exceed 200 feet per minute when a guide line is used to control personnel hoists. When a guide line cannot be used, the rate of travel of the employee being hoisted shall not exceed 100 feet per minute."

The March 26, 2002 directive changed OSHA's inspection policy by removing the restriction on hoisting employees on the hoist line to their work stations if those work stations were lower than 200 feet.

The hoist's rear drum for personnel lifting meets these standards and can not exceed the 200 fpmmaximum.

|

|

Hello, and thanks for this wonderful look into the world of tower construction. Once this tower reaches the full height, how long will it take the workers to climb to the top and how long, on average, will they stay on the tower? - Birmingham, AL

A tower worker in excellent shape, carrying 45 pounds of safety equipment and tools, will be able to climb to the top in approximately one hour or more. But the rule is, always climb at a safe, comfortable pace. There is an interior climbing ladder and safety climb device. It's difficult to get an average time for maintenance work. It could be a simple repair of an obstruction light beacon that could be completed within an hour. It is not uncommon for a tower technician to be on a tower for up to six hours or more troubleshooting and repairing an antenna or feedline.

|

|

Do new guy wires stretch? If so, how often does the tension have to be adjusted? - San  Antonio, TX Antonio, TX

Yes they do (this is called construction stretch), but where a spelter socket, that is, a factory installed termination at each end is used, the cables will be measured under prestretch of up to 40% of their breaking strength in order to minimize the amount of construction stretch.

Once the proper guy wire tension is pulled, the wires will still expand and contract based upon the temperature. The design tension of the guy wires is based on an initial temperature of 60 degrees Fahrenheit (16 degrees C). Minor variations in guy tensions are to be expected due to temperature and low wind speed conditions. Possible causes can be initial construction loosening, anchor movements, base settlement, or connection slippage.

Maintenance and condition assessment must be performed in three-year intervals for guyed towers and five-year intervals for self-supporting structures - or after severe wind and/or ice storms or other extreme conditions, according to TIA/EIA 222-G.

|

|

What caused the failure of the original tower during the tornado? - Summerville, SC

The FM station suffered complete devastation of their tower and transmitter site on February 2,  2007 from a 4:00 a.m. tornado that had also killed 13 people. The Groundhog Day twister toppled it on top of the concrete block transmitter building. 2007 from a 4:00 a.m. tornado that had also killed 13 people. The Groundhog Day twister toppled it on top of the concrete block transmitter building.

Whenever there is a tower collapse engineers try to identify why the structure failed. They can utilize this information for a more detailed analysis and better correlation between damage and wind speed studies and to identify if it was a product or installation problem that caused the failure.

In this instance, the anchors remained in place, but there could be no determination why the tower failed because the tornadic activity, recorded at 165 mph, was so severe, it caused the structure to become too twisted to perform any meaningful analysis.

|

|

What was the purpose of the short tower section they stacked before stacking the top piece?

- Scott City, KS

Numerous other viewers had the same question, some wanting to know why the section wasn't placed on top. The FAA placed a height limitation on this structure - including the antenna height - of 1500'. This short section, measuring in at 12.5', was necessary to reach 1499'.The smaller section could have been designed to support the 90' mast, but it would have been more complicated.

The above ground level height must also include the LED beacon and lightning protection. For those people who are not inclined to climb to the top and drop a tape to measure it, actual heights are:

| |

No. |

Feet |

Feet |

| Beacon and Lightning Protection |

1 |

6 |

6 |

| Antenna |

1 |

90 |

90 |

| Top Section |

1 |

23.5 |

23.5 |

| Short Section Below Top |

1 |

12 |

12 |

| Standard 30' Section |

45 |

30 |

1350 |

| Bottom Pivot Section |

1 |

11.5 |

11.5 |

| Base Foundation |

1 |

6 |

6 |

| TOTAL HEIGHT ABOVE GROUND LEVEL: |

|

|

1499 |

|

Where was the tower fabricated? Did someone oversee the fabrication process on a daily basis? How long has that person been fabricating towers? - Huntingdon Valley, PA Where was the tower fabricated? Did someone oversee the fabrication process on a daily basis? How long has that person been fabricating towers? - Huntingdon Valley, PA

The tower was manufactured in Stainless LLC's Pine Forge world-class facilities, about fifty miles northwest of you.

The plant complies with the requirements for certification by the American Institute of Steel Construction and the plant manager is on the floor all day, every day and has been at Stainless for over 30 years.

|

|

Are there any pictures of the base foundation and guy anchor foundations as well as general specs on them? - Skillman, NJ Are there any pictures of the base foundation and guy anchor foundations as well as general specs on them? - Skillman, NJ

The tower base, at right, was retrofitted to meet the structure's new loading. The tower is supported by a base foundation and nine anchors. The base foundation is a pad several feet thick on top of four piers, each 58 feet deep.

The anchor system is comprised of nine anchor points, three in each of three directions, 120 degrees apart. The anchors are 317, 690 and 970 feet from the tower base. Hundreds of yards of concrete and tens of thousands of pounds of re-enforcing steel were used. Plus, footings are used to support the coax bridge from the tower base to the entrance at the building, 100-feet from the tower.

|

|

Can you please give us some information on the crew? How many men are working on this project? How many years of experience do they have? - Washington, DC

The number of men staffing a tower erection varies depending on the circumstances.

As few as five to as many as ten for big projects such as candelabra towers. The experience of this crew varies from approximately five years to 25 years.

Five men are pictured at right working at the tower's base.

|

|

I guess the camera makes the tower look out of plumb sometimes when it zooms to the top. What are the tolerances that are allowed on a tall broadcast tower versus a normal cell tower? - Rock Hill, SC

That is a requirement that is oftentimes misunderstood. TIA 222-G doesn't play favorites between tall broadcast towers and their shorter cousins, treating them all with the same tolerance. The antenna and tower standard states, "The horizontal distance between the vertical centerlines at any two  elevations throughout the height of the structure shall not exceed 0.25 percent of the vertical distance between the two elevations for latticed structures and 0.50 percent for tubular pole structures." elevations throughout the height of the structure shall not exceed 0.25 percent of the vertical distance between the two elevations for latticed structures and 0.50 percent for tubular pole structures."

Using those factors for a 200' tower, 0.25 percent of 200' is .5' or 6", allowing the structure to be off 6" between two vertical points, whether it is 40' or 200'. Therefore, a 400' tower could be out of plumb 12" and a 100' tower's acceptable tolerance would be 3", according to the standard.

Therefore, a 1000' tower could lean symmetrically as much as 30" and this Central Florida tower would be in compliance at 45" out of plum, almost half of the 96" width of the tower's face.

It is rare that a specification will cite more conservative tolerances since most manufacturers and erectors will ensure that the structure's vertical tolerance is considerably less than TIA 222-G's maximum. Some end users let it be known that their preference is to not have the crosshairs of the transit stray far from a tower leg as it sweeps up the tower.

|

|

What type of antennas and transmission lines are planned for the tower and what is the maximum allowable antenna loading on the tower? - Gladstone, Australia What type of antennas and transmission lines are planned for the tower and what is the maximum allowable antenna loading on the tower? - Gladstone, Australia

The tower was originally designed to support:

-

One top mounted FM antenna at 1460' fed with 4" T/L

-

One TV antenna at 1281' fed with 6" T/L

-

One 8-Bay FM antenna at 1200' fed with 4" T/L

-

One 12-Bay FM antenna at 1095' fed with 4" T/L

-

One 10-Bay FM antenna at 885' fed with 3" T/L

-

and a host of dishes, two-way communications antennas and feed lines, lower on the tower

|

|

Is there any favorite web site that contractors use to keep an eye on the weather to plan their day's work and to make sure that crew personnel will not be up on a tower when it is  lightning? - Lakeland, FL lightning? - Lakeland, FL

There are numerous web sites that are monitored by supervisors and project managers to view storm, lightning and tornado warnings as well as heat indexes to plan their work. However, the tower rigger is typically aware of potential storm and lightning hazards long before management provides him with the information since he can immediately see approaching storms while working on the tower.

Almost every climber can speak of a time when lightning struck nearby while they were on a tower; a select few have been on a tower when it was hit multiple times, but they remained unharmed. When a climber sees lightning nearby or hears thunder, he should come down quickly in an orderly and safe fashion, a more difficult process on a tall broadcast tower when you don't have the luxury of a man basket or elevator to quickly lower you.

There are approximately 45 deaths attributed to lighting each year with Florida listed as having the most fatalities. There have been no known deaths of tower workers working on or around steel, but the highest percentage of fatalities most years are those people carrying iron -- golfers.

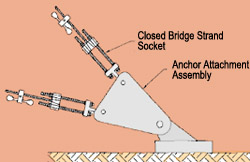

I would like to know more about how the wire is secured in the bridge strand socket. I sure enjoy watching the work and appreciate the effort of all the participants. I am a retired two-way shop owner and tower contractor, but still climbing safely on my own 200-foot tower at  age 71! - Tampa, FL age 71! - Tampa, FL

The end of the bridge strand enters a tapered opening in the socket housing and the broomed end is wrapped around a separate component call a wedge or cone. The arrangement is put in place, and the load is gradually eased onto the bridge strand. As the load increases, the wedge becomes more secure, gripping the bridge strand tighter. There are two styles: the closed type has a U-bolt with or without a bearing block in the U of the bolt, the open type has two eye-bolts and a pin. Structural engineers will oftentimes design a socket system to meet the anchorage requirements of the tower being built.

Many tower erectors are familiar with the Rocket Socket system by Preformed Line Products. It employs the same principal but has retaining rod subsets that surround the wedge and the bridge strand.

|

|

It looks like the tower will have 15 bands of alternating aviation orange and white (they all look like 100 feet) when the tower is completely erected. I was always under the impression that you painted a tower in seven equal bands? Am I wrong? - Suffern, NY

You're correct, but only if the tower is 700 feet AGL or less. The lighting standard says that for each additional 200 feet you must add one additional orange and one additional white.

What are the OSHA rules regarding allowing a rigger to work on a tower in rainy or other inclement weather such as heat or cold? Must they stop anytime it rains? - Beckley, WV

There are no OSHA rules that identify whether or not it is permissible or safe to work in the rain, and a light rain will oftentimes find crews weathering the environment. Severe rain, cold or heat is not specifically addressed by the federal agency. However, an employer is required by OSHA's General Duty clause to responsibly assess the workplace for hazards, evaluate those hazards and implement policies and procedures to protect their employees. specifically addressed by the federal agency. However, an employer is required by OSHA's General Duty clause to responsibly assess the workplace for hazards, evaluate those hazards and implement policies and procedures to protect their employees.

It is expected that an employer, or supervisor, shouldn't let anyone climb or perform any other work activity if it appears that there will not be a reasonable level of comfort and safety when the weather is bad. Wind speeds are also not addressed by OSHA. Engineered picks and/or professional knowledge have to be applied, especially when working on tall towers where top wind gusts can be considerably higher. Safety regulations are necessary and must be observed, but the key to safety is hazard assessment.

|

|

I love your site and the opportunity to watch them stack out this monster. I've never done anything on this scale in my career. I am curious as to what equipment is being used to take the pictures and how is the backhaul connection made to get  back to the internet? Is it wireless? - Baskerville, VA back to the internet? Is it wireless? - Baskerville, VA

The camera is a Hark VCR-100 modified to operate with the unique observation challenges of the tower construction project. It is a full pan, tilt, and zoom camera with a 20+ zoom capability. It is remotely controlled over a wireless back haul, in this case, a PCS service. Hark's customized service monitors the camera connection, archives snapshots and creates animated movies from snapshots. The camera is controlled remotely by WirelessEstimator.com via a web browser using Hark's server.

What will you guys think of next to beat this? I've emailed this link to all of my office employees, and for the first time ever, I want them to spend time on the internet. Although the largest we've ever built was a 500-foot guyed tower, I want them to have a better understanding of what our field people do on a daily basis. Are you going to be doing any additional projects like this in the future? - Chicago, IL

We have had requests from other companies to provide similar coverage for their upcoming tower builds and we're anxious to present another real time installation as soon as possible.

Will you be providing one condensed video of the entire project? - Franklin, TN

Yes. After the project is completed we will be doing a time lapse of the major installation events.

|

|

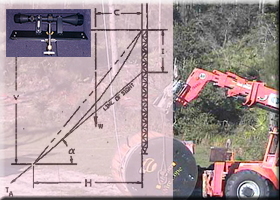

I have been working on cell towers for seven years and I was  wondering what a back leg standoff is and how does it work? - Cincinnati, OH wondering what a back leg standoff is and how does it work? - Cincinnati, OH

It is a pulley device utilized by the rigger to assist the load line to reach the back leg of the tower that is furthest away from the working face where the gin pole is.

The most I’ve ever tensioned was 7/8” guy wire, but I’ve never done anything in bridge strand sizes. What do these larger size wires have to be tensioned to? - Albuquerque, NM

The seven guy wire levels, the bridge strand size and their initial tensions for this tower are:

1 1 1/16” 15,000#

2 1 ¼” 22,000#

3 1 1/8” 16,100#

4 1 ¼” 22,000#

5 1 ¼” 22,000#

6 1 3/8” 27,000#

7 1 ½” 34,000#

Sign me up, I want to work up there with those guys. I have eight years' experience in underground utility construction, but I now see that there's more excitement above ground. How do you apply for one of these positions? - Cape Girardeau, MO underground utility construction, but I now see that there's more excitement above ground. How do you apply for one of these positions? - Cape Girardeau, MO

It's not quite that easy. These top men have been learning their profession for many years. It's not a position that you will be hired for. You'll have to work the ground for some time and learn by training and observing. If you want to jump into the industry right away, there are numerous companies that are willing to hire someone who is green, but has a good work ethic and the ability to climb, but it will be primarily cellular-related work. You can begin your search here, but no matter where the company is located, like your home state's motto, they're going to insist: Show Me! If your only interest in the job is a perceived "excitement", you may not be making the right career choice.

|

|

Why is the bottom of the tower shaped like a "V"? It seems odd that this huge structure  can be supported on that pin point. Why not support it on all three points of contact instead of one? - Canonsburg, PA can be supported on that pin point. Why not support it on all three points of contact instead of one? - Canonsburg, PA

The bottom section doesn't lose any structural integrity by having the legs taper toward the center. This 11.5-foot pivot section is designed this way so that the entire structure can rotate slightly when the tower is subject to extreme wind gusts. What keeps the base in place is that it sits upon the base section plate embedded in the foundation and the guy anchors keep the tower from moving horizontally. Plus, the tension of the guy wires and the weight of the structure - approximately 350 tons - secures it quite nicely.

Engineer Simon Weisman of Weisman Consultants, says it is normal in self supporting towers to have the base wider than the parts above it. In that instance the base actually narrows. The reason is that while self supporting towers resist all of the horizontal load at the base of the tower, guyed towers resist most of the horizontal load at the guy levels and very little at the base.

Allowing the base to rotate slightly eliminates all the bending loads that the base would otherwise have to take. Since you don't need to resist moment at the base, you can bring the legs to a point, thus saving a lot of material and trouble. You could bring the legs straight down and still have a pinned base, but that would require building a very large frame to transfer the loads from the three legs to the single base pin that would accommodate the desired rotation.

It doesn't look like too much is going on after they stack the sections. What do they do the rest of the time? - Toronto, Canada

On some days it appears that there is very little activity. That is clearly not the case. Although you might only see 90 feet of stacking on a given day, there is considerable work involved in installing the conductors and lighting system, and ensuring the safety and proper maintenance of the track pole, winch and other equipment. Also, much of the activity is not within camera range such as pulling many thousands of feet of up to 1-7/16" bridge strand to nine guy anchor locations, installing them and tensioning the tower to the proper specifications to ensure that it is plum and maintains its structural integrity before additional sections are erected.

|

|

What kind of lighting is being installed on the tower? - Corpus Christi, TX

It is red LED lighting. Instead of high intensity lighting, the station owner decided to paint the tower for daytime visibility and use the red lamping system during nighttime hours. Painting the structure while the sections are on the ground, although difficult, is considerably easier than after the tower is erected. When the structure has to be repainted to be in compliance with FAA requirements for visibility to pilots, the cost can be in excess of $65,000.

In height, how does this tower compare with other towers in the rest of the country? - Montclair, NJ

The country's and world's tallest broadcast tower is located in Blanchard, North Dakota where KTHI-TV's guyed tower easily pierces the clouds at 2,063 feet. This Florida tower squeaks by the tallest building in America, the Sears Tower at 1,450 feet, but ably towers over the Empire State Building's 1,250 feet. There's a fine future for the Daytona Beach-area tower. It's designed for a future steel height of 1,599 feet with 100 feet of mast to measure in just shy of 1,700 feet.

Watching the tower stack in Daytona is great. I've learned a lot. Can someone please send me information on how the gin pole is attached to the tower and how does the pole go up and down the face of the tower. Please send diagrams and information if it is available. - Miami, FL

Your request is similar to many others that we have received. We'll let the ANSI/TIA-1019 document be your guide. The TIA standard for steel gin poles used for installation of antenna towers and antenna supporting structures is the authoritative source. The pole being used has a track to support the pole during its raising and lowering. Tracks used to guide and support gin poles during the jumping process can not be used as a bridle or mid-level support unless they are specifically designed for such use.

As a desk jockey, I thought I knew quite a bit about what it takes to erect a tower. Whoops! You are showing me how little I know. I'm finding each day's events to be addictive. I can't see the anchors. Do they use pre-forms for the guy wires? - Ashtabula, OH

For attachment hardware, a closed bridge strand socket is used. For our next tall tower presentation we will make sure that we have the capability to view the installation of the guy wires at multiple anchors.

Thank you for this wonderful armchair view of construction. How much does one of those tower sections weigh? - Conyers, GA

They start at 14,000 pounds. Some additional information about the tower can be found at: Just the tower facts, Mam!

|

| |

|

Do you have any questions regarding this project? Email them to us and we'll be pleased to answer them.

|

|

All photography and content © WirelessEstimator.com

|

|

WARNING : This generic, non-exhaustive overview of a 1,500' tower being constructed is only intended to serve as a useful starting point for industry information. Proper training,  professional knowledge and oftentimes licensing are required prior to anyone providing product design, selection, installation, and construction/development-related activities. professional knowledge and oftentimes licensing are required prior to anyone providing product design, selection, installation, and construction/development-related activities.

This information is neither presented to instruct nor teach anyone in the proper or safe methods of any aspect of wireless design or construction. To ensure minimum exposure and to determine compliance for a safe working environment, you must obtain the advice and guidance of an industry professional and you must not rely upon any information, installation or safety procedures seen during the tower's construction. construction. To ensure minimum exposure and to determine compliance for a safe working environment, you must obtain the advice and guidance of an industry professional and you must not rely upon any information, installation or safety procedures seen during the tower's construction.

Failure to meet these minimum requirements and appropriate compliance responsibilitiescan result in serious injury or death to you or your fellow workers. All aspects of wireless construction are hazardous by nature. You have the sole responsibility to act safely and with caution prior to performing any construction-related task.

|

|

|