Installation Information

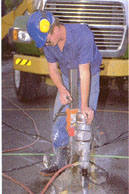

Core Drilling and Concrete Cutting

If you are providing new transmission lines into an existing concrete shelters or installing a rooftop application where the equipment room is eight floors below, you are no stranger to concrete core drilling and cutting requirements.

Many contractors will hire a company specializing in core drilling and concrete cutting after weighing the following considerations:

- What are the rental costs of the required equipment?

- What will my total cost be when I add in the weighted average employee expense for their coring and cutting time as well as picking up and returning the equipment?

- Are my crewmembers proficient at core drilling so that I will not be exposed to paying for damaged bits and equipment?

- Would my company be better served if their time were dedicated to their areas of expertise?

All coring and cutting companies will require site-specific information to quote your project accurately. The following pricing average was received from multiple contractors for drilling a 3” and 6” diameter hole into a 6” concrete equipment building, 7’ above ground level, 15 miles from their All coring and cutting companies will require site-specific information to quote your project accurately. The following pricing average was received from multiple contractors for drilling a 3” and 6” diameter hole into a 6” concrete equipment building, 7’ above ground level, 15 miles from their  office: $325.00. Additional 3” holes were $45.00; 6” holes, $75.00.A rental company average for a rig to wet or dry core the same holes was $130.00 per day ($350.00 weekly); a 3” bit was $65.00 per day ($175.00 weekly) and a 6” bit, $95.00 per day ($240.00 weekly).A walk behind floor saw, 14”, gas, was $60.00 per day, ($180.00 weekly).Some wireless contractors purchase core bits that work well with their hammer drills and rotary hammers. office: $325.00. Additional 3” holes were $45.00; 6” holes, $75.00.A rental company average for a rig to wet or dry core the same holes was $130.00 per day ($350.00 weekly); a 3” bit was $65.00 per day ($175.00 weekly) and a 6” bit, $95.00 per day ($240.00 weekly).A walk behind floor saw, 14”, gas, was $60.00 per day, ($180.00 weekly).Some wireless contractors purchase core bits that work well with their hammer drills and rotary hammers.

If it makes dollars and sense either to hire a coring and cutting contractor or to rent your own equipment, we urge you to contact our valued coring companies and rental firms.

Core Bit Trouble Shooting

GLAZING (Bit stops drilling or is very slow)

Cause: Too much feed pressure

Remedy: Open bit with abrasive material (Sand pot, concrete block, chop saw blade)

BENT SEGMENTS

Cause: Aggregate is too hard

Remedy: Use a softer bond

Cause: Too much feed pressure and not enough water

Remedy: Repair the bit if possible. Ease up on feed pressure and increase water flow.

LOST SEGMENTS

Cause: Steel reinforcing rod

Remedy: Ease up on feed pressure. Use a higher quality bit and increase the water flow

Cause: Not enough water to cool properly the bit

Remedy: Increase water flow

Cause: Drill rig is not properly anchored

Remedy: There are three ways of anchoring a rig – Standing on the rig is not one of them

CORE HANGS UP

Cause: Not enough water to remove slurry

Remedy: Remove bit and drive core out with a spike through the hub. Increase water flow

Cause: Core barrel is dented because of hammering on it to remove hung up cores.

Remedy: Repair the barrel and increase water flow

Factors that affect bit Performance

Speed (RPM): If the speed is too high the bit will polish; too low and the job will take too long.

Power: Necessary to maintain the proper cutting speed. If you are using a portable generator, you may not have enough power.

Water: Not too little and not too much. You will identify the right amount when it removes the slurry and keeps the cut clean.

Aggregate: You cannot see it until you are done, but a good driller can feel the right speed and pressure to cut varying types.

Steel: Slows the cutting process. Maintaining drill motor speed is important. Do not push the bit too hard.

Proper Alignment: Necessary for good bit life. This means the rig must be anchored properly. A rig can be anchored with concrete anchors, vacuum or a post jack.

|