Service Information

Geotechnical/Foundation Engineers

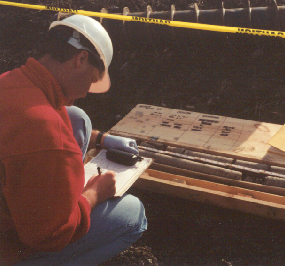

The integrity of a wireless construction project clearly hinges upon the selection of the contractor’s geotechnical and structural engineering firms. Whether it is Phase l or Phase ll environmental assessments or subsurface investigations and recommendations, the engineer’s role is pivotal to the project’s success. The most crucial elements, however, are the formulation of recommendations and the design of the structure’s foundation. Some engineering firms and engineers provide both disciplines. the engineer’s role is pivotal to the project’s success. The most crucial elements, however, are the formulation of recommendations and the design of the structure’s foundation. Some engineering firms and engineers provide both disciplines.

Since 30% to 40% or more of a wireless project’s installation cost can be attributed to the tower’s foundation, the type and size of the foundation design can severely affect the final cost.

Two competent structural engineers, receiving identical base reactions and boring logs, will oftentimes provide similar foundation designs, with dissimilar dimensions. One could easily require 10% more concrete, reinforcing steel and associated labor, costing more than $6,000.00 in some instances. Or, one type of design preference by an engineer might be more expensive than an alternative design.

The differing sizes of a similar design can be attributed to a host of reasons; a key explanation provided by many engineers is their local knowledge of bearing capacities, skin frictions and other considerations based upon the area’s rock and soil conditions. The differing sizes of a similar design can be attributed to a host of reasons; a key explanation provided by many engineers is their local knowledge of bearing capacities, skin frictions and other considerations based upon the area’s rock and soil conditions.

Generally, tower manufacturers’ foundation designs are larger and more costly to install than designs provided by an engineering consultant. One manufacturing engineer attributes it to the need of the manufacturer to provide a more conservative design to mitigate additional liability exposure from a non-core area of their business.

In some wireless construction builds, the project manager incorrectly believes that he is saving his company money by ordering split spoon sampling with limited subsurface depths and locations. The math is easy. The savings come from a cost effective design that is based upon adequate subsurface knowledge.

Industry recommendations for geotechnical investigations and reports include:

Boring Logs and Reports:

- Date, sampling methods, number and type of samples

- Description of the soil strata according to the Unified Soil Classification System

- Depths at which strata changes occur referenced to a site benchmark elevation

- Standard Penetration Test blow counts for each soil layer

- Soil density for each soil layer. Unit weight of the soil, buoyant unit weight, if submerged

- Ultimate bearing capacities for each soil layer or at the recommended bearing depths.

- Allowable bearing pressure (values versus depth and settlement expected), mainly at tower base

- For expansive soil conditions, the active zone of influence and recommendations for design

- Elevation of free water encountered and the ground water depth below grade to be considered for design as well as seasonal levels

- Maximum and average frost penetration depth and frost depth to be considered for design

- Soil electrical resistivity, Ph values and corrosive nature of soil

- Recommendation of the foundation design best suited for existing soil conditions and recommendations for alternate foundation types

- Report of construction problems anticipated, including any casing required, etc.

- Pertinent soil design data and recommendations and any other variables that will affect the installation and design

For Drilled Pier foundations, the following information should be provided:

- Ultimate tip bearing capacity

- Ultimate skin friction for each soil layer

- Lateral modulus of soil reaction for each soil later

- Ultimate soil strain at 50% of ultimate compression for each soil layer

For Rock Anchors, the following information should be provided:

- Type and condition of rock

- Rock quality designation, RQD

- Percent of rock sample recovered

- Ultimate bond stress in the interface between the rock and grout

- Ultimate sheer strength

We recommend that you contact our listed geotechnical and structural engineers specializing in foundation design and recommendations to obtain additional information about their services, capabilities and experience.

Design/Recommendation Fees:

Foundation design by a structural engineer will vary according to  the type and size of tower and soil characteristics (which determine the complexity of the design) and whether the engineer is licensed in the wireless project’s state. The consultant can provide a number of designs, such as spread footings, caissons, piles, and belled piers based upon soil conditions and the particular needs of the client. the type and size of tower and soil characteristics (which determine the complexity of the design) and whether the engineer is licensed in the wireless project’s state. The consultant can provide a number of designs, such as spread footings, caissons, piles, and belled piers based upon soil conditions and the particular needs of the client.

|

Budgetary Design Pricing

|

| Structure |

Drilled Pier |

Pad/Pier |

Pad/Pier

Deadman |

| Monopole |

$1,200 |

$1,200 |

--- |

| Self Supporting |

$1,200 |

$1,200 |

--- |

| Guyed (3 Anchors) |

$1,300 |

$1,300 |

$1,300 |

| Guyed (6 Anchors) |

$1,375 |

$1,375 |

$1,375 |

A report from a geotechnical engineer can be budgeted at $3,500. Soil boring fees will depend upon the type and variations expected in the soil, the lay of the land, and the requirements of the structure and will usually be included in the fee for the geotechnical investigation and report.

Foundation rehabilitations are commonplace

The need to place additional tenants on existing communications structures can require reinforcement of the tower and its foundations. Most existing structures were designed for minimal loading; future loading capabilities on newer towers are reaching capacity.

As-built foundation designs are not always available as tower drawings, and the consultant is required to utilize various methods to assess the installed foundation’s design. Radiography is a non-destructive procedure for identifying reinforcement steel within the structure, but it can be a considerable expense. Investigating the design of existing foundation structures are specialties of a few companies.

Reviewing the original design recommendations, combined with the actual construction records may reveal some latitude for increased loading, but when the foundation is inadequate, a new design must be provided based upon working area and cost considerations. the actual construction records may reveal some latitude for increased loading, but when the foundation is inadequate, a new design must be provided based upon working area and cost considerations.

It may be possible to improve the foundation’s capacity with remedial techniques, such as compaction grouting. Additional elements, such as mini piles, helical anchors, and additional surface beams or connectors may be used.

A "collar" on the shaft is another option. It can increase the upper moment capacity, the shear capacity, provide additional compressive load capacity and provide additional ballast for overturning or uplift. The collar must be dowelled into the existing shaft to affect interaction.

|