Product Information

Rock Anchors

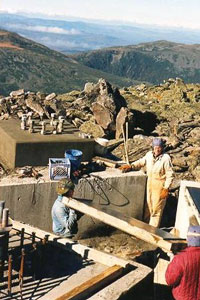

When excavation costs to install a normal foundation are not economical or they are impractical, rock anchors and bolts are used to counteract uplift and other forces acting on tower foundations, developing their resistance to forces by means of high strength, high stress steel bars embedded into competent bedrock. The tension bar, sometimes referred to as a tendon, is bonded to the drilled rock socket wall with high strength grout.

After anchor installation, the free length of rock anchors are tensioned or loaded, while rock bolts have their bars fully grouted, typically with a fast setting resin grout, and cannot be post-tensioned. Both rock anchors and bolts can have very high load capacities, but tensioned anchors are more commonly specified for monopole and tower installations to resist steel fatigue.

During stressing with a hydraulic jack, the free stressing length of  the anchor elongates. Once stressed to a specified load, the tensile forces in the free stressing length of the rod are locked in by transferring the load from the hydraulic jack to the anchor plate, thereby permanently loading the anchor. the anchor elongates. Once stressed to a specified load, the tensile forces in the free stressing length of the rod are locked in by transferring the load from the hydraulic jack to the anchor plate, thereby permanently loading the anchor.

Prior to selecting a rock anchor system you should core the rock 10’ to 30’, and identify the competence of the rock to support the rock anchor loads. It is also advisable to do a preliminary analysis of corrosion potential of the rock to identify the type of anchor required. Each project’s anchors are different depending upon the lateral and vertical forces. It's required, as a minimum to identify the following:

- Type and condition of rock

- Rock quality designation

- Percent of rock sample recovered

- Ultimate bond stress in the interface between the rock and grout

- Ultimate sheer strength

The project specifications will usually identify the type of anchor system required to meet the structure’s reactions and may list a specific manufacturer’s product. If an approved equal is allowable, ensure that an alternate choice has been approved prior to providing a quotation. Pricing and installation methods can vary considerably. The project specifications will usually identify the type of anchor system required to meet the structure’s reactions and may list a specific manufacturer’s product. If an approved equal is allowable, ensure that an alternate choice has been approved prior to providing a quotation. Pricing and installation methods can vary considerably.

We recommend that you contact our valued rock anchor manufacturers and distributors for your site-specific requirements for their advice, or contact a rock anchor design professional specializing in product selection and installation supervision.

|