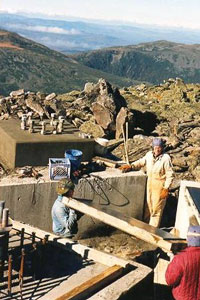

Installation Information

Rock Anchors

Your profit margin will be as low as the anchor depth if you don’t carefully review the installation specifications, equipment and additional requirements necessary prior to submitting your proposal for a rock anchor project. Some rock anchor foundation installations are relatively easy and only require resin grouted rock bolts; others require post tensioned rods that call for specialized testing and installation equipment.

Many projects will have a full time engineer on site to inspect the rock coring and slushing of the anchor holes, water pressure testing of the anchor holes, proper installation and grouting of the anchors and performance testing of all of the anchors.

For a post tension expansion anchor, each manufacturer will have their set of procedures, but the typical installation requires using a rotary percussion drill to drill a straight hole. The depth is typically over drilled 12” beyond the placement length of the rod. Drilling diameters will vary from 1” to 3” depending upon the size of the rod. Depths can reach 30’ or more. over drilled 12” beyond the placement length of the rod. Drilling diameters will vary from 1” to 3” depending upon the size of the rod. Depths can reach 30’ or more.

Prepare the plate bearing area with a flat surface by using a quick setting grout perpendicular to the bolt axis. Carefully clean out the hole. Place the nut, washer, bevel washers, if required, and plate on the rock bolt and push or hammer the bolt into the hole to the correct embedment depth.

As you torque the setting tool on the threaded anchor rod with a pneumatic or hydraulic torque wrench, it will expand the mechanical anchor at the end into the rock

Place the jack and frame over the bolt and attach the test rod and couplings to the bolt. Attach the test nut and test plate over the test  rod on top of the jack. Test the rock bolt by tensioning the jack to the required test load but do not exceed the yield strength of the anchor. Adjust the loading of the jack to the required final tension and lock in the final pre-stress load. rod on top of the jack. Test the rock bolt by tensioning the jack to the required test load but do not exceed the yield strength of the anchor. Adjust the loading of the jack to the required final tension and lock in the final pre-stress load.

Through an opening in the bearing plate, pressure grout the anchor bolt socket until a stream of grout is seen coming out from around the plate or grout tube. Some rock anchor bolts have hollow cores and require a tube adapter to the outer end of the tensioned bolt.

The type of anchor and coring depth as well as the type of foundation to be installed to accommodate the monopole or tower will influence your pricing. If you don’t have a great deal of experience, network with another company that installed similar projects. Your anchor supplier may be able to provide further assistance. The type of anchor and coring depth as well as the type of foundation to be installed to accommodate the monopole or tower will influence your pricing. If you don’t have a great deal of experience, network with another company that installed similar projects. Your anchor supplier may be able to provide further assistance.

The test and installation equipment is not available in most contractor rental locations, but is obtainable through rock anchor suppliers. Make sure that you have included all of the tools necessary for your project, according to the specifications, and identify how long the project is going to take. Weather and site problems could push you into the next rental period. The test and installation equipment is not available in most contractor rental locations, but is obtainable through rock anchor suppliers. Make sure that you have included all of the tools necessary for your project, according to the specifications, and identify how long the project is going to take. Weather and site problems could push you into the next rental period.

We recommend that you contact our valued rock anchor installation professionals or contact a rock anchor design professional specializing in product selection and installation supervision.

|