Installation Information

Ground Rods

Soil conditions can sometimes be unrelenting when driving a ground rod which is normally an easy installation task. If the wireless grounding system requires numerous rods it is advisable to review the available soil borings for rock and other materials that might require drilling or other installation techniques. Chemical Rods may be an alternative for difficult soil conditions.

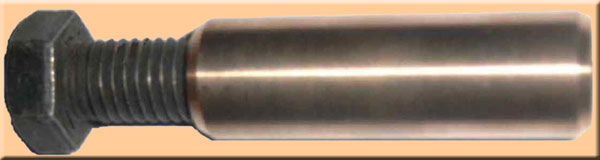

Hammer drills with a sleeved bit are most commonly used to drive the rod. A high strength steel driving stud is also available for  sectional rods to eliminate damage to the ground rod threads. For those purists who prefer to use a 10-pound beater on an unthreaded rod, driving sleeves are available sectional rods to eliminate damage to the ground rod threads. For those purists who prefer to use a 10-pound beater on an unthreaded rod, driving sleeves are available to prevent the top from mushrooming. to prevent the top from mushrooming.

A product fabricated by installers is a flat metal plate capped 2” pipe with bent reinforcing steel handles welded to the side. This will allow one or two men to raise the pipe above the rod and let the force-dropped pipe serve as a hammer device. Another product uses a smaller pipe, but a weight is welded at the top. This will help to keep the ground rod from bending when it hits solid resistance. Digging a small hole and filling it with water can oftentimes provide an easier installation.

The default pricing of $29.65 (6 rods or less) is an average charge, while on site, for a subcontractor to install a ground rod based upon soil conditions that do not require any special installation methods. Prices will vary depending upon site conditions and location. The default pricing will change based upon the number of rods to be driven for the project. Material is not included. The default pricing of $29.65 (6 rods or less) is an average charge, while on site, for a subcontractor to install a ground rod based upon soil conditions that do not require any special installation methods. Prices will vary depending upon site conditions and location. The default pricing will change based upon the number of rods to be driven for the project. Material is not included.

We recommend that you contact our valued grounding installation companies to obtain additional information about their services, capabilities and experience.

|